![]()

![]()

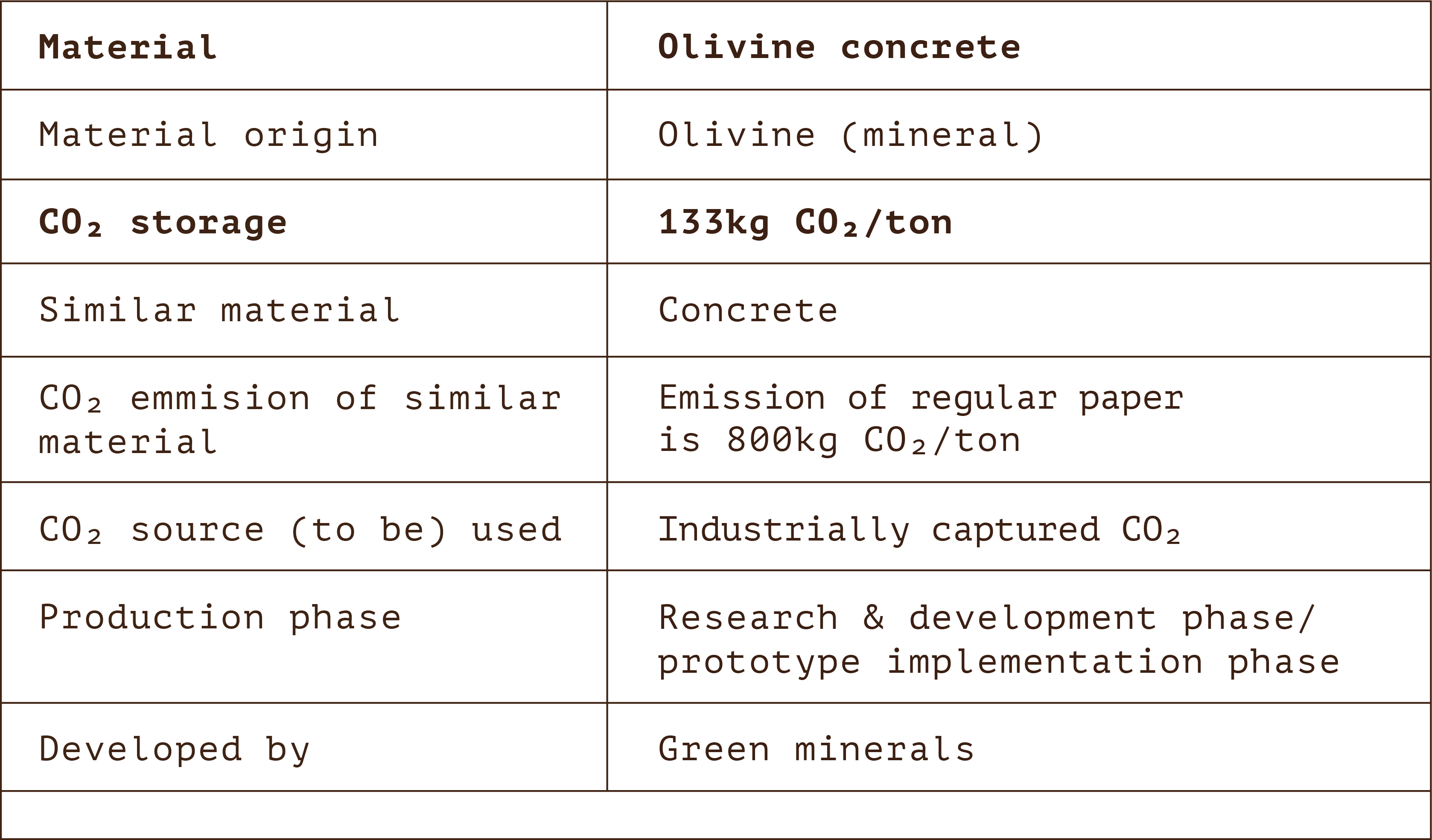

Olivine concrete.

This concrete is one of the first carbon negative concretes in the world. It draws on the natural CO2-sinking properties of the mineral olivine and captures 133kg of CO2 per tonne of concrete.

After water, concrete is the most heavily used material on the planet. Its fabrication is also incredibly destructive, releasing large amounts of CO2 into the atmosphere at every step of the process. Currently, 800 kilograms of CO2 are released into the air for every tonne of concrete produced. Then, after a life cycle of about 50 years, concrete loses its integrity and needs to be recycled. The special olivine concrete developed by Green Minerals could change this polluting process. The olivine concrete is made from captured CO2 produced by concrete factories. The captured CO2 is then used as a raw material to make a new environmentally friendly concrete.

Olivine concrete uses the power of olivine to trap up to 130 kilograms of CO2 per tonne of concrete. This is done by replacing cement in the concrete recycling process with CO2 reacted Olivine. The CO2 is captured directly from the concrete factory, preventing it from making its way into the atmosphere. This process could in term be developed to make a carbon-negative concrete. At the end of its life cycle, buildings will need to be demolished. The concrete waste product will then be ground up and mixed again with CO2 reacted Olivine. Afterward sand, gravel and water will be added with fresh cement for a new round of construction. This process could make concrete a recyclable product, without having to make new cement which releases carbon dioxide in its production process.

This would allow the factories making cement to capture the CO2 they are already producing and turn it into one of the building blocks of the houses we live in.