![]()

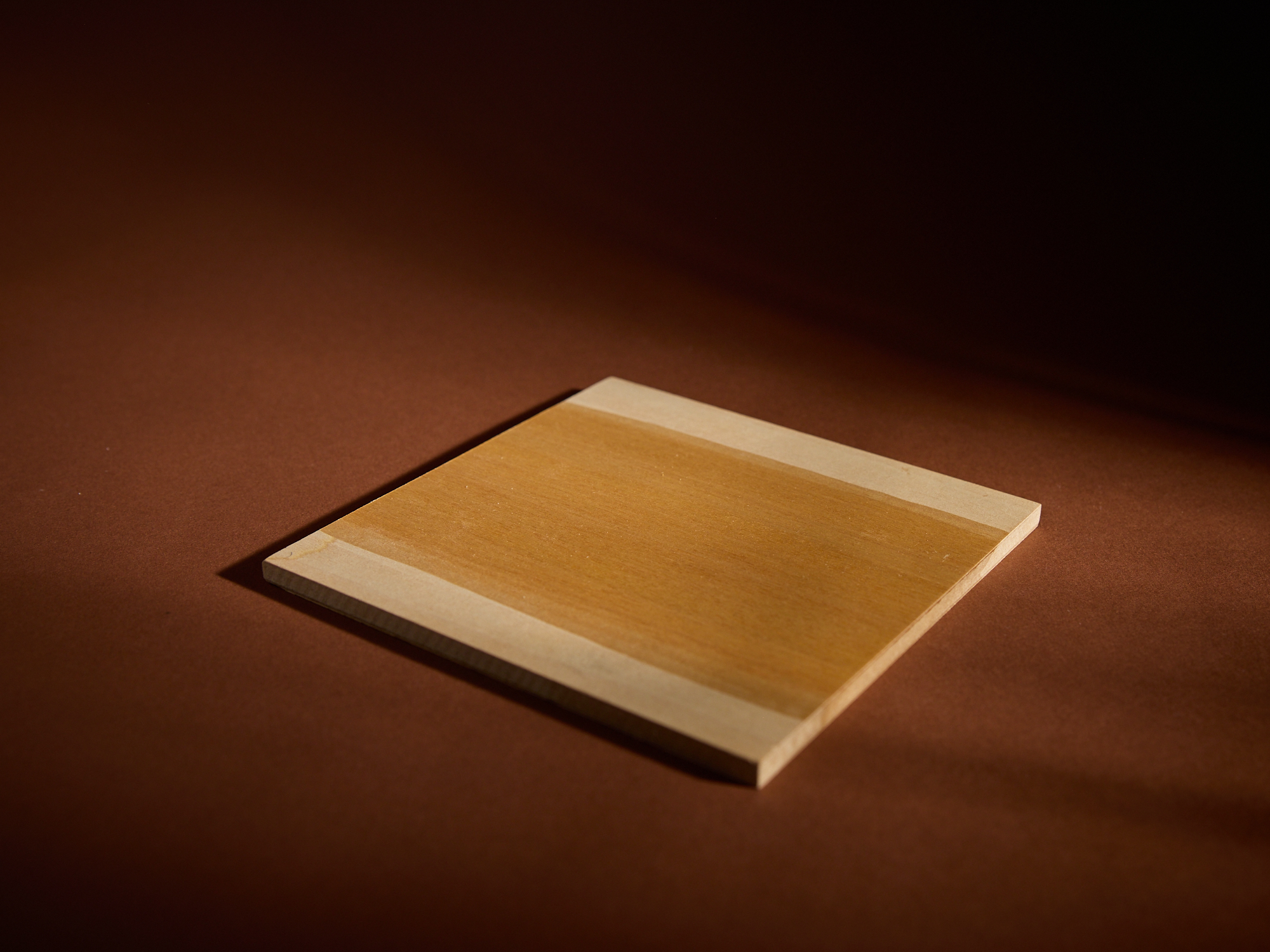

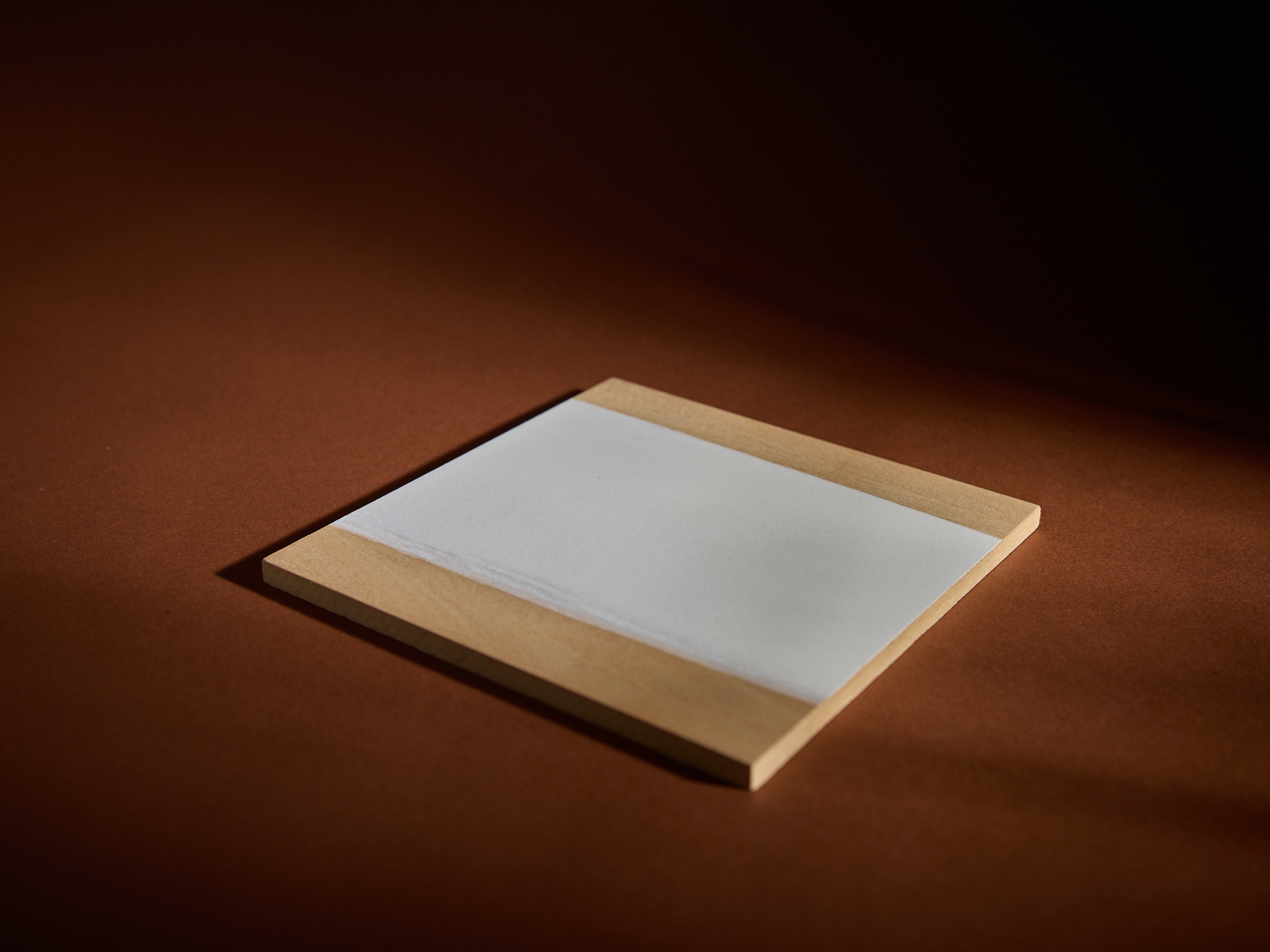

Polyurethane coating

Flue gases from the steel manufacturing industry contain a mixture of carbon dioxide (CO2) and carbon monoxide (CO), harmful gases for the environment but valuable components for chemical production of synthetic materials. Polyurethane coatings are a recently developed synthetic material in which 20% of the oil-based reactants are replaced by waste gas from the steel industry.

Currently, the majority of polyurethane products are reliant on the extraction of crude oil and are extremely damaging to the environment. Nevertheless, polyurethane takes on a seemingly irreplaceable role in society. It is used to make many everyday products such as: shoe soles, mattresses, clothes, printing inks, adhesives and coatings for wood or metal. In the quest to find more durable material compositions for plastic, Carbon4PUR is a pioneering research project, led by polymer developer Covestro, with 14 partners from 7 European countries. Their research has shown that the usage of crude oil, in the production of plastics, could partially be replaced by the use of CO2 and CO.

This new polyurethane is different from normal polyurethane products. It is based on undervalued CO waste streams that are captured directly from steel plants. This process reduces the amount of crude oils needed for the production with 20% compared to conventional coatings. Because toxic CO waste is captured directly from chemical plants, it does not escape into the atmosphere where it would contribute to the greenhouse effect. This product is a first steps toward fully renewable polyurethane coatings.

This material was created within Carbon4PUR, a European consortium working to generate an economic application to CO/CO2 waste streams. The project received funding from the European Union’s Horizon 2020 research and innovation programme

Covestro is a company that specialises in the production of new polymer materials.

Megara Resins is a chemical company that focuses on creating alternatives to petroleum in polyurethane industries. They centre carbon-based solutions and low carbon footprint processes to create the same products that are currently entirely reliant on petroleum extract.