![]()

Waste Concrete

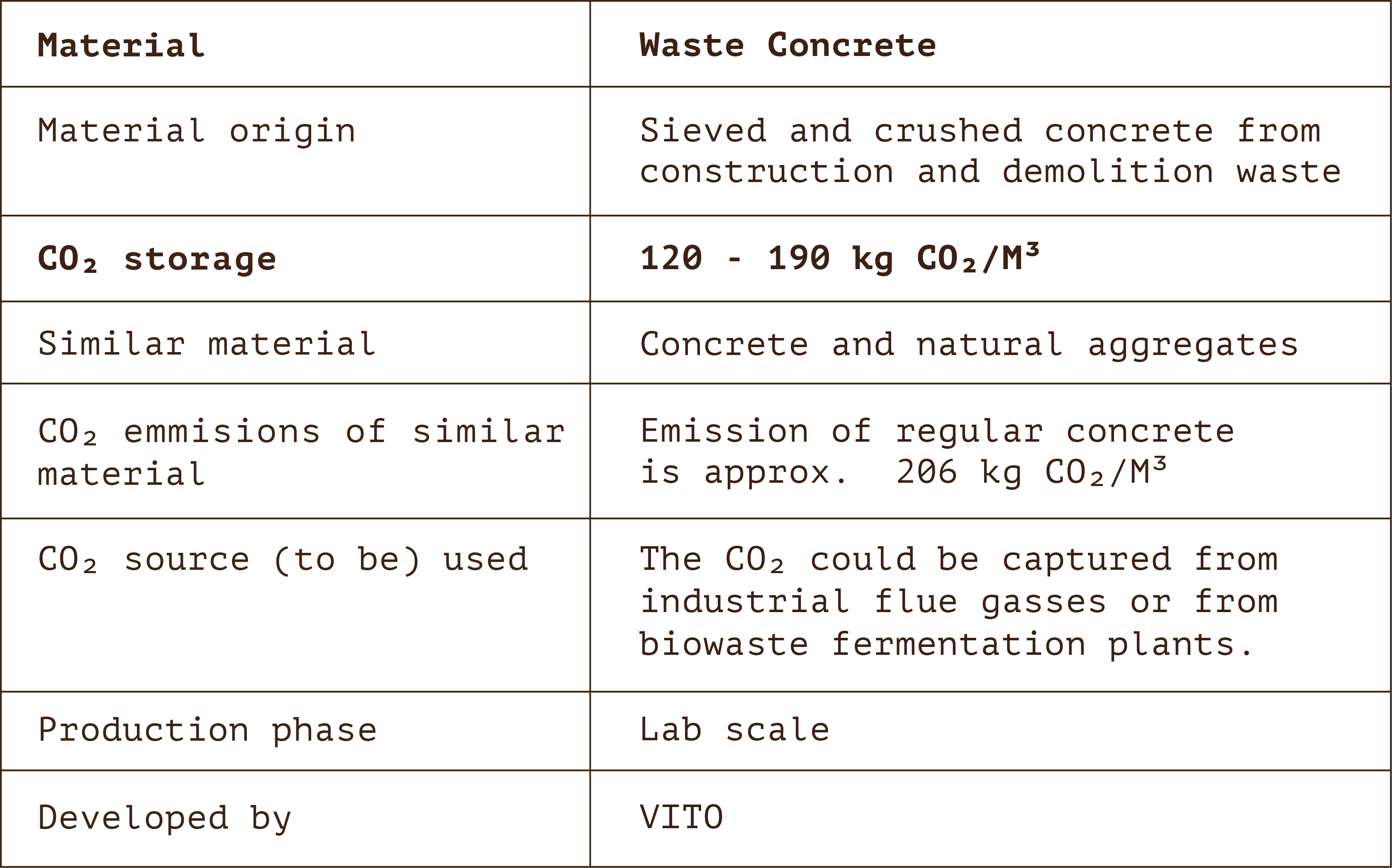

In spite of being portrayed as durable, concrete has a relatively short life span of about 50 years. Currently, the recycling possibilities of concrete are limited. This is because once recycled, the concrete particles lose cohesion. Recent research has shown that a new concrete-like material (carbstone) can be formed, using waste-concrete and CO2 as a binder.

In the production process of this waste-concrete Carbstone, it is possible to store up to 600 kilograms of CO2 per tonne of cement which is forever captured into the material. As a result, this material could shift the balance of CO2 emission in the concrete production-chain.

Construction and demolition waste (C&DW) is one of the largest waste streams in the European Union. It accounts for approx. 30% of all waste generated in the EU. Of this, up to 70% is waste concrete. Currently, only one third of the concrete waste is recycled. This is due to the high water absorption of the recycled material, which affects the quality and durability of the new concrete.

Pulverised concrete however, was discovered to be promising in the development of carbon-negative materials like Carbstone. During the production process CO2, that was directly captured from industrial emissions, reacts with the formula creating a concrete-like material. Because of this CO2 is transformed into a raw material which brings it back into the value chain. The formula for this new type of concrete was developed by the Flemish Institute for Technological Research (VITO) and could radically improve the possibilities for recycled concrete.

Carbstone was developed by VITO - an organisation that specialises in clean technology and sustainable development. With this technology, it is possible to create a range of different products including roof tiles, clinkers and building blocks, while permanently sequestering CO2.